Partners

We collaborate with industry-leading companies that provide innovative solutions to enhance manufacturing efficiency, precision, and reliability. Below are some of the trusted partners we work with to bring high-quality products and services to our customers.

Modern Industries offers a unique combination of advanced machining services, high-performance product lines, NADCAP-certified heat treating, and accredited laboratory testing—all under one roof. Their broad capabilities and deep engineering experience make them a versatile partner across manufacturing, aerospace, automotive, and heavy industry.

Modern’s machining division operates over 65 CNC machines and supports full-scale production with TS-16949 and AS-9100C certifications—helping customers reduce lead times, cut transport and supplier costs, and accelerate time to market.

Their mPower Workholding line—including SpeedLoc, ModLoc, SpinLoc, and SpinSelect—provides fast, flexible fixturing solutions that drive efficiency, improve changeover speed, and lower operating costs. Our customers have successfully integrated mPower with Tombstone City fixtures to unlock new capabilities in demanding production environments.

Modern’s Heat Treat Division is one of the largest in northwest Pennsylvania and offers NADCAP-certified processes from two locations, while their state-of-the-art labs deliver a full suite of analytical, chemical, metallurgical, and NDT testing services.

With a team of skilled engineers, certified technicians, and on-site support, Modern Industries delivers trusted results across every stage of the manufacturing process.

Gorilla Mill manufactures high-performance solid carbide end mills and cutting tools engineered for demanding machining applications. Known for their aggressive geometries, proprietary coatings, and innovative designs, Gorilla Mill products deliver exceptional performance in hard materials like stainless steel, titanium, and Inconel.

Their product lineup includes everything from general-purpose tools to application-specific cutters like the Phenom (optimized for high-temp alloys), Silverback (for ferrous metals), and the Sasquatch series (for extreme material removal). Whether it’s roughing, finishing, or high-velocity milling, Gorilla Mill tools are built to outlast and outperform the competition.

Distributed by over 300 partners worldwide and trusted in aerospace, defense, and heavy manufacturing, Gorilla Mill has earned a reputation as the go-to choice for CNC machinists who want speed, power, and reliability—without compromise.

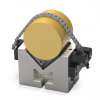

Industrial Magnetics is a global leader in the design, engineering, and manufacturing of permanent magnets and electromagnets for industrial applications. Their product line spans magnetic lifting, fixturing, separation, conveying, and automation—delivering solutions that improve safety, efficiency, and precision across a wide range of manufacturing environments.

What sets IMI apart is their ability to combine off-the-shelf product availability with highly customized engineering. Whether you need a standard magnetic tool or a completely bespoke system built to unique specs, their team applies a consultative, solutions-driven approach to every challenge.

IMI’s magnets are built to last, with a focus on performance, craftsmanship, and long-term reliability. Their North American manufacturing footprint and global distribution network ensure quick delivery and responsive support wherever customers are located.

At Tombstone City, we’ve seen firsthand how IMI’s magnetic solutions enhance our warehouse applications. They’re a valued partner whose innovation and quality align with our own mission to support high-performance manufacturing.

Carbinite specializes in metallurgically bonded textured coatings that enhance grip and wear resistance for a variety of industrial applications. Their carbide alloy coatings, applied through Electro Spark Deposition (ESD), provide exceptional bond strength without causing annealing or distortion—making them a superior alternative to thermal spray and hard chroming.

One of Carbinite’s key advantages is its ability to improve workholding and gripping power in machining and fabricating. By increasing the coefficient of friction, their coatings enhance holding power, allowing for higher feed rates, optimized production efficiency, and extended tool life. This makes them a valuable solution for reducing or eliminating workholding slippage in machine tools, fabricating equipment, and primary metal processes, including steel and aluminum mills.

Our customers have utilized Carbinite to add enhanced grip to our SVF modular vise systems, improving stability and performance in demanding machining applications.

Carbinite’s coatings are guaranteed not to chip, flake, or peel, and their experienced technicians can apply or reapply coatings on-site to minimize downtime and keep operations running smoothly.

Badass Workbench designs and manufactures some of the toughest, most reliable workbenches on the market—built for professionals who demand durability without compromise. What began during the agricultural boom of 2008 has grown into a trusted, nationwide brand with a full line of heavy-duty workbenches, welding tables, and custom-built solutions.

From their earliest designs—steel-topped tables built from repurposed pallet racking—to their current lineup of over 65 models, Badass Workbench has stayed true to its roots: no shortcuts, no gimmicks, just American-made craftsmanship built to take a beating and keep going. With rugged construction, customizable options like drawers and shelves, and unmatched weight capacity, their benches are made for serious work in the toughest environments.

Today, Badass Workbench serves customers across the U.S. and around the globe. If you’re looking for an industrial-grade work surface that won’t back down, these are the guys to call!

In 2022, TombstoneCity launched an initiative to partner with nonprofits and other organizations in the machining world.

Learn more about these partnerships and how you too can support their causes:

Following the model of Homeboy Industries in Los Angeles, Rise Up Industries’ Reentry Program opened in Santee in March 2016. It assists previously incarcerated, formerly gang involved individuals to successfully reenter society; thereby, reducing the gang population and the recidivism rate.

A key component of Rise Up’s Reentry Program is the Machine Shop Social Enterprise, where members are trained for careers as CNC (Computer Numeric Control) machine operators. 100% of Reentry Program graduates are immediately employed upon graduation as CNC machine operators.