Tombstone City is the leading supplier of tombstones, angle plates, sub plates, and modular vise systems in North America.

Our mission is to provide you with high-quality, dependable products so you can manufacture more efficiently.

We believe in building long-term, trusting relationships with our customers. Together, we can help create solutions for all of your manufacturing needs.

Knowledge and Experience You Can Trust

TombstoneCity™ was founded by Andy Popky, who has long had a passion for fixing things and solving other people’s problems. As a child, Andy was fascinated with anything mechanical and later took that enthusiasm into his first job at a scale factory. Andy was known to spend his lunch breaks in the machine shop asking questions, learning, and getting hands-on experience. Over the next two decades, Andy expanded his knowledge and expertise by working in all aspects of the machinery industry.

In 1999, Andy received a phone call from his good friend and customer, Randy Neubauer of Min-Max Machine. Randy needed tombstones for a new HMC they had purchased and trusted Andy for his connections and problem-solving skills. Andy sourced a top-quality tombstone at a great price, and on that day TombstoneCity was born. Over 20 years later those tombstones are still in use at Min-Max’s shop and we are now the largest supplier of tombstones, angle plates, sub plates, and modular vise systems in North America.

TombstoneCity, a family-owned and operated business, strives to provide you with personal, attentive customer service. If you have a workholding problem or need, call TombstoneCity today and speak directly with Andy or his daughter Jackie.

With over 45 years of combined experience, our team can guide you towards the most efficient solution to get your job done.

Services

TombstoneCity provides a full line of highly productive

work holding products that are designed to streamline the

production process on VMC’s and HMC’s. including:

- Tombstones

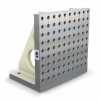

- Angle Plates

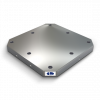

- Sub Plates

- Custom Fixtures

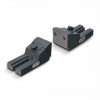

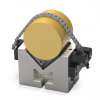

- Modular Vises

- 5 Axis Vises

Work Holding Solutions

Tombstones are designed to fit both inch & metric pallets, they are available in a wide range of sizes & shapes. Angle plates are designed for use on a variety of machine types such as horizontal & vertical machining centers or boring mills. Sub plates are designed to streamline setups and save time and money. Our product line includes highly productive: CNC and manual vises, 5 Axis vises, rotary table work holding solutions for VMC’s. These products give you increased versatility at your machining centers. The new VB 5 axis vise has been redesigned to eliminate production bottlenecks.

Product Integration

Our product line can be integrated into your current and future machining programs. TombstoneCity has a work holding product that will meet your application’s demanding requirements. Metalworking tombstone for horizontal machining centers. Large cast iron angle plates are ideal for boring mills. Horizontal tombstone for manufacturing of aircraft parts. TombstoneCity products are designed to work with all machine tool builders such as: Makino, Mazak, Matsuura, OKK, Toyoda, Okuma, Kiwa, Kitamura, Haas, Hyundai WIA, Niigata, DMGMori, Doosan, Enshu, Shibaura Machine, SNK, Mitsui Seiki.

All TombstoneCity products are engineered from the ground up, guaranteeing their productivity, strength, precision, and long term durability.

Custom Solutions

In addition to our extensive standard product line, we offer complete turnkey solutions to help solve the most demanding applications, Custom products are offered in Cast iron, Cast aluminum, Cast steel, and various grades of ToolsSteel. Our facilities feature late model high-precision machines including a new large capacity Yasda HMC capable of machining up to a 6 foot cube. We understand work holding problems and deal with complex machining fixture building on a daily basis. We keep over 500 products in stock and most items are available for immediate shipping.

Industry Knowledge & Expertise

TombstoneCity brings many years of experience in providing work holding solutions to CNC machining. Our know-how in work holding helps integrate into today’s demand for high productivity and quality driven manufacturing. We offer the full range of work holding solutions and dedicated service that has made TombstoneCity a highly successful work holding supplier. Our workholding engineers are highly-respected in all the major fields such as: automotive, aerospace, defense, medical and other metalworking industries to improve quality and reduce cycle times.

We always offer our customers Lowest Cost, Highest Quality, and Satisfaction Guaranteed.